The Hidden Costs of Traditional Construction

Traditional construction materials like wood and concrete come with unseen costs—project delays, rising labor expenses, weather-related setbacks, pest infestations, and long-term operational inefficiencies. In this article, we’ll unpack the real challenges of conventional building methods and show how Prime Manufacturing’s high-quality steel structures deliver faster, smarter, and more cost-controlled solutions.

Why Construction Cost Predictability Matters

When you’re planning a building—whether it’s a commercial warehouse, a retail center, or a personal workshop—the budget is more than just the materials and labor on paper. True construction cost involves everything from weather delays and unexpected repairs to operational inefficiencies long after the project is complete.

This is why material choice matters. Traditional materials like wood and concrete often look economical at first glance, but come with hidden costs that snowball over time. In contrast, steel offers predictability, speed, resilience, and superior long-term value.

At Prime Manufacturing, we’re committed to empowering decision-makers with the right knowledge to protect their investment and grow it. Let’s take a closer look at where traditional construction bleeds money, and why steel buildings stand out as the smarter alternative.

The Hidden Costs of Traditional Construction

Project Delays: Weather, Labor Shortages, and Site Challenges

Traditional Construction Pitfalls:

Weather Dependency: Wood and concrete builds are highly sensitive to rain, snow, and temperature swings. Wet conditions can delay framing, concrete pours, and even interior work.

Labor Bottlenecks: Traditional projects rely on multiple trades, from carpenters to masons. Scheduling delays with just one trade can halt the entire project.

Site Prep Requirements: Wood and concrete builds often demand extensive grading, curing times, and site conditioning that prolong project timelines.

Each day of delay increases labor costs, equipment rental fees, and in some cases, penalty payments on financing agreements.

Material Waste and Theft

Traditional Construction Pitfalls:

Jobsite Waste: Wood and concrete generate significant waste—cut-offs, mispours, breakage—that must be hauled offsite at additional cost.

Material Theft: Lumber and copper are high-theft materials on open job sites, leading to unexpected losses and insurance claims.

Waste removal and security expenses add thousands to project budgets, and insurance premiums rise after claims.

Rising Labor Costs

Traditional Construction Pitfalls:

Skilled Labor Shortages: Qualified framers, masons, and concrete finishers are in short supply, driving up labor rates.

Extended Build Times: Traditional builds take longer to complete, compounding labor costs even further.

Higher per-hour rates and longer schedules double the financial impact on projects.

Pest Damage and Rot

Traditional Construction Pitfalls:

Organic Vulnerabilities: Wood structures invite termites, carpenter ants, rodents, and mold, leading to expensive treatments, repairs, and insurance claims.

Maintenance Cycles: Regular inspections, pest control treatments, and wood replacements become part of ongoing property management.

Over 10–20 years, pest and rot repairs can easily add 10%–20% to the original construction cost.

Insurance Costs and Claims

Traditional Construction Pitfalls:

Higher Risk Profile: Wood-framed structures face higher premiums for fire, storm, and pest-related claims.

Frequent Claims: Repairs after weather events or pest infestations can drive up premiums further or lead to non-renewal.

Over the building’s lifespan, traditional structures cost significantly more in insurance payments compared to steel buildings.

Operational Inefficiencies

Traditional Construction Pitfalls:

Poor Energy Efficiency: Wood and concrete builds often require costly retrofits for insulation, HVAC upgrades, or window replacements to stay efficient.

Space Limitations: Traditional designs sometimes limit floor plan flexibility, making future expansion costly or impossible.

Operational overhead stays high, while flexibility to adapt to growth or changing needs is limited.

How Prime Steel Buildings Eliminate Hidden Costs

Predictable Timelines and Faster Build Speed

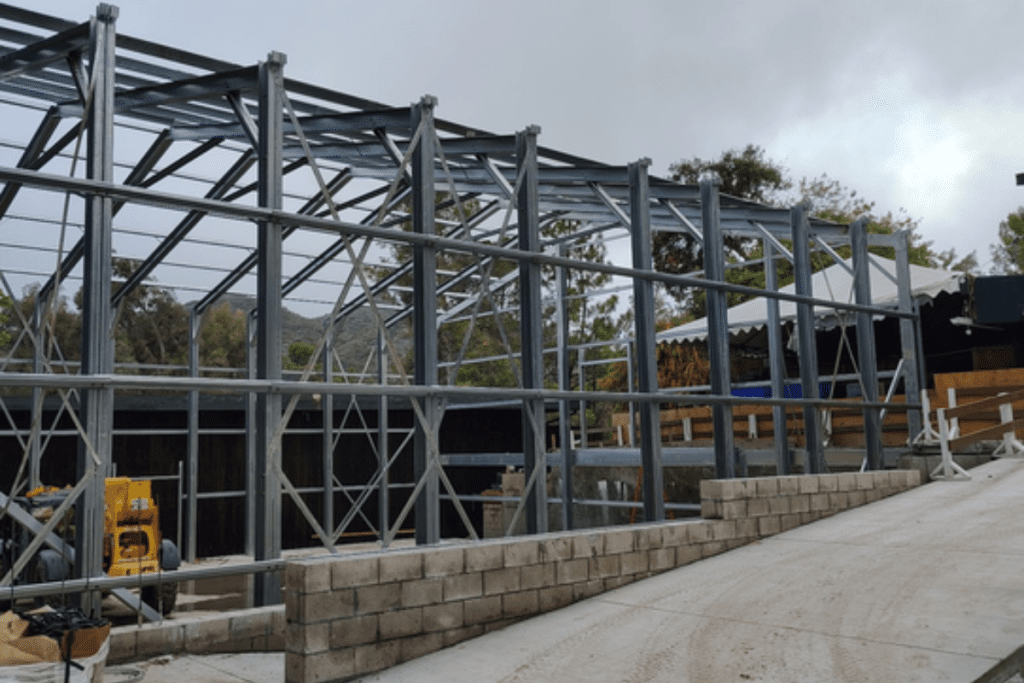

Prefabrication Advantage: Prime’s steel buildings are precision-fabricated off-site, minimizing onsite labor and weather delays.

Rapid Assembly: Building frames and panels arrive ready for installation, reducing construction timelines by 30–50%.

Faster builds mean faster occupancy, revenue generation, or operational readiness.

Minimal Material Waste

Pre-Measured Components: Steel parts are cut and punched in the factory, leaving almost no onsite waste.

Recyclable Materials: Any excess steel can be recycled easily, supporting sustainability goals.

Lower hauling and landfill fees, reduced environmental impact, and cleaner job sites.

Lower Labor Costs

Simplified Installation: Less specialized labor is needed to erect a steel building compared to framing or masonry.

Streamlined Coordination: With fewer trades involved, project management is easier and more cost-efficient.

Reduced labor expenditures keep projects on or under budget.

Superior Resistance to Pests, Fire, and Mold

No Organic Material: Steel does not support mold growth or attract pests.

Non-Combustible: Fire risks are dramatically reduced, improving life safety and lowering insurance costs.

Minimal ongoing maintenance and lower repair costs over the building’s lifetime.

Lower Insurance Premiums

- Reduced Risk Profile: Insurance companies often offer lower premiums for steel buildings because of their superior resistance to fire, pests, and storms.

Thousands saved annually on insurance, improving overall operational margins.

Operational Flexibility and Efficiency

Wide Clear Spans: Prime steel buildings offer column-free interiors, maximizing usable space.

Easy Expansion: Adding space is straightforward and cost-effective with modular steel design.

Energy-Efficient Options: Insulated panels, reflective roofing, and modern HVAC integrations keep operational costs down.

Buildings adapt easily to growth, new technologies, or changing operational needs.

How Steel Outperforms Traditional Building in Different Industries

Warehousing and Logistics

Problem with Traditional Construction: Expensive expansions, pest issues in stored inventory, and insurance headaches.

Prime Solution: Durable, expandable steel warehouses that protect assets and minimize operating expenses.

Retail and Commercial Spaces

Problem with Traditional Construction: Limited customization, slow builds leading to delayed openings.

Prime Solution: Customizable steel retail centers with fast deployment, tailored to branding and spatial needs.

Manufacturing and Industrial Facilities

Problem with Traditional Construction: Long build times, limited floor space, and high retrofitting costs.

Prime Solution: Clear-span steel structures that allow maximum floorplan flexibility, rapid construction, and easy equipment fit-outs.

Agricultural Structures

Residential and Recreational Buildings

- Problem with Traditional Construction: High maintenance costs for garages, workshops, and backyard spaces.

- Prime Solution: Long-lasting, low-maintenance steel garages, guesthouses, and rec rooms that enhance property value.

The Prime Manufacturing Difference

When you partner with Prime, you’re not just choosing a building—you’re choosing:

- Decades of Engineering Expertise

- Certified Quality for Your Local Building Codes

- Fast, Reliable Manufacturing and Delivery

- Custom Designs to Match Your Operational Goals

- Eco-Friendly, Sustainable Construction Practices

We help eliminate the risks that plague traditional construction, giving you a building that works as hard as you do.

Cut Hidden Costs with Prime Steel Buildings

Traditional construction often hides its real price tag under layers of delays, repairs, and long-term inefficiencies. But when you choose steel—especially with Prime Manufacturing—you choose speed, predictability, cost savings, and structural excellence. Protect your investment from the start. Build smarter. Build stronger. Built with Prime. Ready to design your steel building? Contact Prime Manufacturing today for a custom quote and 3D design consultation.